Wood Hammer Mill

Before making pellet with your pellet making machine, you need to resize your raw material so that they are fit the pellet machine to process pellets, thus the hammer mill is necessary. A hammer mill is a kind of supporting machine to make the size of raw material within 4-5mm.

Application of wood hammer mill

Wood hammer mill is widely used in the processing of pine, poplar, poplar, fir, bamboo and other trees, as well as thatch, corn stalk, sorghum stalk, all kinds of plate scrap, waste wood board packing box, wood chip, and other fibrous material chip.

Advantages of wood hammer mill

- Reasonable design, simple and compact structure.

- Safety, durability, and high production efficiency.

- The whole set of equipment is driven by only one motor. The noise is small and the work is stable.

- Low price, low energy consumption and high output.

- The quality of finished sawdust is good, and the processing cost is low.

Working principle of wood hammer mill

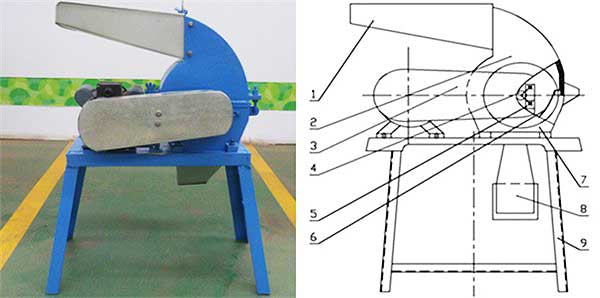

Wood hammer mill adopts blade cutting and high speed airflow impact, double functions of collision and pulverization, and it can accomplish micro material sorting and processing at the same time. In the cutting and grinding process of the blade, the rotor produces a high speed air flow and rotates with the cutting direction of the blade, The material is accelerated in the air flow, and repeatedly impact, the material is crushed simultaneously, accelerate the crushing rate of materials.

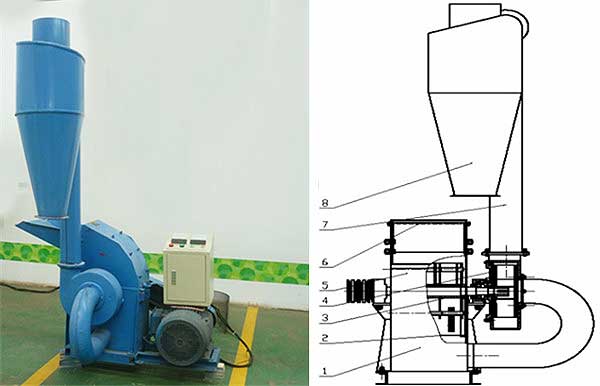

Structure of wood hammer mill

The main machine consists of three parts: the rotor, the upper body and the lower body. Crushing chamber adopts multi-stage crushing process and fine crushing principle device, which is characterized by large impact, high production efficiency and fine crushing ability.

The sawdust crusher consists of main engine, fan, analyzer, powder collector, dust collector and other parts. Each component has compact structure and reasonable layout, its outstanding feature is convenient operation, safe use, good sealing, small noise.

Parameter of wood hammer mill

| MODEL | POWER | WEIGHT(kg) | DIAMESION(mm) |

|---|---|---|---|

| FSC200-160B | Single,3 phase,1.5Kw | 75/85 | 750x450x730 |

| FSC200-160Q | 3.0hp | 65/75 | 920x650x740 |

| FSC300-200B | Single,3 phase,3Kw | 120/135 | 1000x750x1120 |

| FSC300-200Q | 5.5hp | 110/125 | 1000x750x1120 |

| FSC420-280A | 15hp,22hp | 370/390,390/410 | 1650x800x1120 |

| FSC420-280B |

3 phase7.5Kw 3 phase 11Kw |

250/270,300/320 | 1200x1000x1220 |

| FSC500-280A | 22hp | 370/390 | 1650x800x1120 |

| FSC500-280B |

3 phase 11Kw 3 phase 15Kw |

470/500,500/530 | |

| FSC500-400A | 55hp |

Cyclone,125/145 Host machine,310/330 Diesel engine,560/590 |

2700X750X920 1150X800X1270 1500X1050X1320 |

| FSC500-400B |

3 phase 22Kw 3 phase 30Kw |

Cyclone 125/145 Hammer mill 585/610 |

2200X1050X1020 1900X1100X1270 |

| FSC500-600B |

3 phase 37Kw 3 phase 45Kw |