M6FY-30/35/40 Roller Flour Mill

Our plant has developed the new style roller flour mill on the basis of adsorbing the advangtage of our existing flour milling machines.

The structure and appearance of this style roller flour mill has owned the state patent.

Featured with compact construction, perfect design; electricity-saving, low noises, high efficiency and low maintenance.

Ideal for milling of wheat, corn, sorghum, cocoa, coffee and other grain material.

| Model |

Output (kg/hour) |

Power (kw) |

Flour Quality |

L×W×H (mm) |

Packing Size in container of 20feet |

|---|---|---|---|---|---|

| M6FY-30 |

300 |

7.5 |

Confirm with the stipulation of GB1335-86 <Wheat Flour> |

1100× 750× 1400 |

1/30 |

| M6FY-35 |

300-400 |

7.5 |

1300× 750× 1450 |

1/12 |

|

| M6FY-40 |

350-450 |

11 |

1300× 750× 1450 |

1/12 |

Description:

The M6FY series flour mill is a kind of small flour milling machines, which the length of roller is below 200mm. The small flour mill for sale have a couple of rollers. The two roller of flour mill is located at a level. Generally, the small flour mill is controlled by hand. Compared to big pneumatic flour milling machines, the small flour mill featured compact structure, small area occupied, low investment, easy operation, suitable for home use or small wheat grinding workshop. Besides grinding wheat, M6FY series flour mill have widely application in grinding corn, sorghum, cocoa, coffee and other grain material. It can be an multi-function flour milling machine.

The M6FY series flour mills can be equipped to small flour milling line with capacity lower than 50 ton per day. Such as the flour milling system developed by our company, 6FTY-18B/C, 6FTF-19, 6FTYF-32, 6FTFZ-37, all of them adopt M6FY series flour milling machines.

The Technological Process of Milling Flour

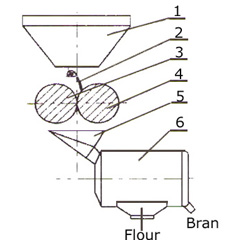

Technological process figure (Fig.1). After being cleaned and tempered (moisture content should be controlled within 13-15%), the wheat is lifted to the

hopper, then the wheat are fed evenly into between the fast roller and slow roller by slow roller, the grinded grain flows into the round separator to sieve flour, the bran flows out through the bran vent. Flour flows out through the flour vent. And then the bran is fed into the hopper by manual or wind power to grind once more. Generally speaking, 5 times will be all left for the processing of wheat milling.

Fig1:

1. hopper

2. deflector

3. fast roller

4. slow roller

5. down reel

6. separator